|

|

|

A History of Technical Innovation

"The Locke Power Reel Mower"

| The Locke Steel Chain

Co. was formed in 1895. S.D Locke had devised a new patented

method of manufacturing link chain from steel strip rather than

the standard method of casting. This was not only a major

industrial innovation but was also considered a technical triumph.

His son, S.D. Locke Jr., of Bridgeport, Conn., his successor,

began design and prototype work in the early 1920ís on a

self-propelled, self powered lawn mower. His interest in lawn

mower development was derived from his dissatisfaction with the

quality and performance of the mowers he had purchased for his

estate. He went about to develop a precision

cutting machine whose quality would span generations. The product

of this effort was the 1925 21" mower, which is the forerunner of

a long line of mowers built to exacting standards of

performance, and durability, as well as bearing the namesake of

the originator.

|

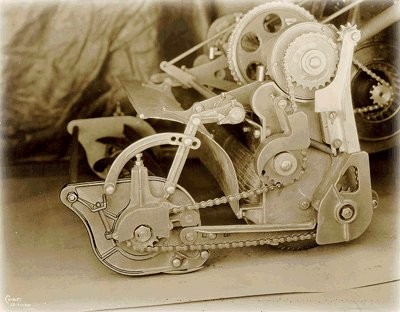

| This mower (see photo at right, June 1926) had a newly developed

Briggs & Stratton "FI" engine, a swinging caster wheel, a

counterbalanced reel that was full floating, a bevel gear

differential housed between two wide traction rollers, and

fingertip controls for reel lift and clutch engagement. So

successful was this first mower that it was decided to enter into

a manufacturing venture dedicated to the advancement and

production of Locke power reel mowers. A team of engineers,

craftsman, and planners set about the work of this project, and

technical achievement was evident in the fall of 1927. |

|

| The following year,

1928, is commonly known as the first model year for the Locke

power reel mower. This new mower was available with such options

as a grass catcher and a back-lapping arrangement. The mower was

known simply as the 25"Power Reel Mower and bears striking

resemblance to the mowers produced today in terms of size, shape,

weight, details such as the tool box, handle-bars, controls, self

tensioning chain drives, and construction in general. Many of the

design and handling features that were present in this first

production Locke mower are firmly embodied in our most recent

models. (Below photo taken March 1928) |

|

|

| After a

successful but limited run in 1928, production was stepped up in

1929 to meet the market demand created by this efficient machine,

and the dedicated people behind the Locke power reel mower proved

more than ready to meet this challenge. (See photo below of

completed mowers taken May 1929) |

|

|

| During the busy year of

1929, the research and development department came up with another

innovation. They took a 25" mower frame, installed a larger

engine, attached side reels to the frame with special carrying

brackets that allowed the side reels to follow the ground contour

like the front reel, and designed a way to get the engine power to

the new side reels. Due to the fact that the 25" mower was

originally designed and built so substantially, a different frame

was not needed to support the extra weight, power loads, and

attachments. This resulted in a mower well suited for large areas

with a price only nominally more than the single mower. The

product of this effort was the 70" Locke triplex, later to become

known as the item #6. (See below photo of prototype triplex taken

October 1929). The following year, 1930, saw the introduction of

the 70" Locke triplex mower, which would become the flagship

product of Locke Power Reel Mowers for the next 50 years |

|

|

| In 1932, a 30"

cut-single unit mower was introduced. Later to become known as

item 5 & 5A, the 30" single became a favorite of landscape

professionals. From a mowing efficiency perspective, it is

interesting to note that a 5" increase in cutting width results in

a 40% increase in productivity. The 25" mower can cut .5 acres per

hour while the 30" cuts .7 acres per hour.

By 1932, the first sulkies were offered. These were ball

bearing units with iron wheels. 1932 also marked the first year

that rubber traction rollers were offered as an option. This

improvement proved to be so successful that, with the exception of

rubber shortages during the war, all mowers thereafter would be

shipped with rubber traction rollers. Several new advances were on

the horizon and in 1933 a 75" triplex was offered. This mower

would cut at the rate of 2 acres per hour and became a favorite

tool of contractors and estate keepers responsible for maintaining

large turf areas. In 1934, pneumatic tires replaced the iron

wheels. Production was suspended in 1942 and resumed in 1946 as

very few units were shipped during World War II.

In 1949, a reverse gear option was offered on the 70", and 75"

triplex mowers. This transmission was specially designed and built

in the same plant as the mowers, as it is today. The reverse gear

transmission uses a planetary gear set, a multi-plate friction

pack, a brake band and drum, and is sealed with oil in its own

housing. The transmission simplified the handling of these heavy

mowers (725 pounds), and was so successful that it was offered on

the 25" and 30" mowers in 1951. (see photo below of Locke 70"

reverse triplex which will later be known as item 10) |

|

|

| After 1959, model #, and

width of cut were associated with item numbers as follows: |

| Item 2 25" single unit

mower |

| Item 5 30" single unit

mower |

| Item 22 30" single unit

mower with reverse |

| Item 6 70" triplex mower |

| Item 10 70" triplex mower

with reverse |

| Item 8 75" triplex mower |

| Item 23 75" triplex mower

with reverse |

| In the late 1960ís, the

mowers were redesigned, taking advantage of many new industrial

processes and the new standard metric size of bearings, shafts and

other power transmission components. Although this was a corporate

move to improve efficiency, care was taken to insure that the

legendary handling, productivity, and quality were not

compromised. In 1966, 7-blade reels were offered as an option and

were highly valued in southern climates. Up to this point, 5-blade

reels were standard on all mowers. |

|

|

|

Locke mowers have been and will

continue to be heavy-duty, precision instruments built to hold up

to the most rigorous demands of landscape professionals. No

capricious model year or cosmetic changes are instituted, although

improvements are continually incorporated into all models. Present

day Locke mowers have an outstanding pedigree and we at Locke plan

to continue to produce mowers that will be recognized around the

world as the ultimate response to the need for the highest degree

of quality lawn care.

|

|

Locke Power Reel Mowers have set the standard for turf care at

some of the most prestigious grounds around the world. These

grounds include the White House, the Kremlin, National Park

monuments, L.A. Dodger stadium, Yankee Stadium, as well as yours.

We welcome your comments and suggestions at Locke. If you do

not presently own a Locke, we encourage you to try out a Locke

Power Reel Mower and experience for yourself Lockeís legendary

cut, performance, and durability. |

|

|

The first riding mower was developed in 1971. It was known as

the Maxi mower. A newly designed chassis, with a front mounted

engine, utilized three 30" reels in order to deliver an 87"

cutting width. The heart of this mower was the new Eaton model 6

hydrostatic transmission that allowed unlimited variable traction

speeds along with reverse in the same control mechanism.

In 1973, Locke reentered the golf market (A putting green mower

was built in the early 1930ís) with a 70" triplex greens mower.

The new mower was called item # 7. They enjoyed only a limited run

and were discontinued in 1976. The Maxi mower was updated and

changed to the Maxi-II in 1974.

1976 marked the first year of the "60 series"mowers. At first,

a 25" single mower, item # 60 was offered. These machines were a

separate product line and were lower in cost than the "standard

series". The sixty series mowers used belts and pulleys instead of

chains and sprockets. This allowed the reel and traction drives to

be engaged with out the clutches and related hardware. Also, a

welded frame replaced many castings further reducing lead times

and expenses. The 60 series mower grew in to a family of mowers

offering everything from the 25" single to 70" and 75" reverse

triplex, and even included a small greensmower. After a successful

run, the 60 series were discontinued in 1983. They are highly

valued today because of the ease of maintenance and the simple

availability of pulleys, belts, etc.

1980 saw the further evolution of the riding mower with the

Maxi-II (Mark-2), and later in 1984 to be renamed the Professional

model 1 (87" cut) and the model 4 (77" cut). These units had foot

controls and electric start Briggs & Stratton 16 hp engines.

1987 marked the first year Honda engines were offered as an

option. These proved to be very smooth running, durable engines

and were used as follows, 5 hp on single units or item 6C, and 8

hp for other triplex mowers. Because of good planning and parts

interchangeability, Honda engines can be fitted to any standard

series Locke from 1932 to present. 1988 saw the introduction of

the pneumatic tire drive system. This option substitutes 4 small

pneumatic tires for the two rubber covered drive rollers and fits

within the same space. These tires greatly increase traction,

which helps while mowing in wet or hilly conditions. These

developments were employed on a 70" triplex with a Honda 5 hp

engine, making it the lightest triplex ever. It was called the

model 6C," Contractor".

In 1996, the R & D department began in earnest with a new

project. It was determined that a lower cost, more versatile

single unit mower was needed. In the spring of 1997, the new

product was offered as the Locke "Commercial Series". It is built

in 25" and 30" cutting widths and comes equipped with a Briggs &

Stratton 5.5hp vanguard engine. This series of mowers combine all

of the qualities that have made Locke a household name, with the

latest in manufacturing technology. This mower incorporates a

"quick adjust" height control system which allows the user to

adjust the height from Ĺ" to 3" in a matter of seconds. This is

made possible due to the fact that the reel runs on a full length

aluminum roller instead of skid shoes, which allows the

overlapping of bedding areas, as well as increases the striping

ability of the mower. This series of mowers also feature operator

presence safety controls. These mowers have quickly become our

number one sellers worldwide and we are expecting great things in

the future.

|

|

|